Total Custom Engineering to Meet Your Application

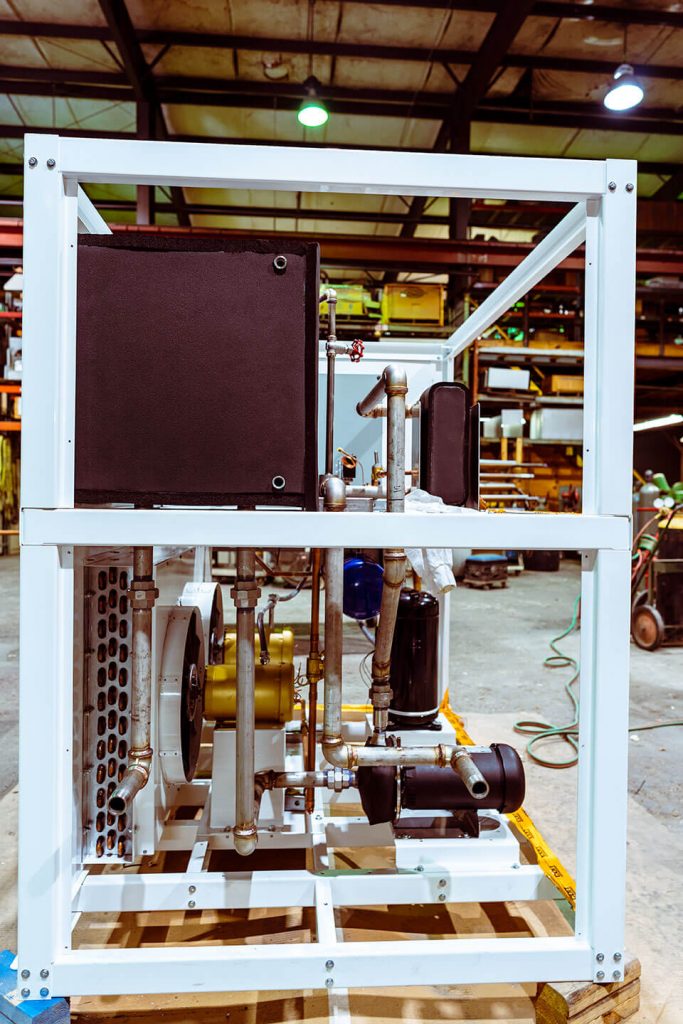

When a standard machine will not meet your particular application, GCI lndustrials can build the exact custom industrial chiller you need. Our standard building blocks can be combined in unique ways to meet your requirements in a cost-effective way.

How To Order

How to Order Icewagon Chillers

- Determine the preferred medium of cooling, Air or Water.

- Determine required cooling capacity in nominal tons (12,000 BTUH per ton).For computer assisted load calculation contact factory and request Technical Support Bulletin REHV1FRM.

- Determine required voltage configuration. For 50 Hertz models contact factory.

- Determine hazard classification per National Electric Code (NEC). For example Class I, Group D, Division 2.

- Select the model number following the order code.

- Scan the “Options and Accessories” listing below and select the desired items. Order by adding and dash and the Compressor Configuration

- For technical or pricing information contact your representative or Sales Engineering at (225)-926-6950.

Additional Options

Outdoor and split systems. Fully stainless models for food applications. DI water, heaters, special paint, lower temperature models, oversize tanks, special pumps, special currents, special weather proofing

- Copper Fin Coils

- SaveCoil™ Coil Coating

- Type 316 Stainless Steel Housings

- Full Corrosion Protection

- Weatherproof Nema 4

- Explosion Proof Nema 7

- Low Ambient Controls

- 100% Redundant Systems

- Automatic Switch Over

- Epoxy Patin with Urethane Topcoat

- Optional Explosion Proof Disconnect Switch

- Other Options include Defrost Timer, Oil Separator, Solenoid Valves, and Crankcase Pressure Regulator

- Cupro-Nickel Marine Condensers and Low Ambient Controls

| Model Number | Description |

|---|---|

| LAC | Low Ambient Controls, for operating when outdoor ambients are below 55° (13° C) |

| BG | BLYGOLD PoluAL spray-applied coil coating on condenser and evaporator coils, additional |

| ECB | BYLGOLD PoluAL spray-applied coil coating, other metal epoxy primed and coated additional |

| SH | Cover housing, Corrosion Resistant Type 316 stainless steel |

| MBS | Mounting Bracket Set, Type 316 SS, for corrosion-resistant support of SafetyCool Air Conditioners |

| EXP | Export Crate, heavy-duty, for rough handling air or sea shipment specify |

| RC | Remote Controls, thermostat, and selector switch |

| SPS | Spare Parts Kit (thermostat, selector switch, run capacitor) |

| CC | SaveCoil 31 Dip applied and baked coating on condenser and evaporator coils, additional |

| EC | SaveCoil 31 Dip applied and baked coil coating, other metal epoxy primed and coated, additional |

| Model No. | Description |

|---|---|

| OR | Off Road Package – Standard base model. Excludes all features in -HWY package |

| HWY | Highway Ready Package – includes surge brakes, spare tire, light and reflector package, license plate holder, VIN registration and certificate of origin. |

| CD | Condensate Pump – a condensate pump located in the evaporator drain pan allows pumping of condensed moisture to a safe location. |

| EH(*) | Electric Heat – Add electric heat for use in heating and cooling applications. Rugged Finned Tubular heating elements available in 15kW, 40kW, 65 kW, and 90 kW on most models. |

| HP | Heat Pump – Adds reversing cycle for heating for outdoor temperatures above 45°F. |

| CM | Cam Locks – Quick connect Cam Lock electrical plugs replace power line cord. |

| DTI | Digital Temperature Indicators – Two digital displays mounted on the control console display supply and return air temperatures. |

| RT | Remote Thermostat – With 125 ft. cord allows temperature control form within the air-conditioned space. Mount Thermostat inside build for precise control. |

| PLX | Plexiglass Cover – Weather tight door with plexiglass window protects the control panel from the elements while allowing operator to view controls. |

| Model No. | Description |

|---|---|

| / SS | Stainless Steel Housing, 14 ga Type 316 with 16 ga access panels, includes option “/EC” |

| TCXP-C-1101 | Thermostat, “Cool” or “Fan Only,” Class I and II, Groups B, C, and D, Division 1 and 2 |

| TCXP-HC-1101 | Thermostat, “Heat,” “Cool,” or “Fan Only”; Manual Switchover, CI. I and II, Grps. B, C, and D, Div. 1 and 2 |

| / EH(kw) | Auxiliary Electric Heat (*), (specify kw) |

| / SH(MBtuh) | Auxiliary Steam Heater, less trap or control solenoid, (specify MBtuh and supply pressure) |

| / FDI | Disconnect Switch with Circuit Breaker Protection, installed |

| / DSI | Disconnect Switch, non-fused, installed |

| / LAC | Low Ambient Control, for operating at ambient temperatures between 0 and 50°F |

| / HGB | Hot Gas Bypass for capacity control |

| / CC | SaveCoil 101 oven baked coil coating on condenser and evaporator coils |

| / EC | Full Corrosion Protection: Non-stainless metal parts epoxy coated; Coils are SaveCoil 101 protected |

| / SDI | Smoke Detector, installed with system interlock |

| / FAD | Manual Make-Up Air Damper |

| / Cu-Cu | Copper coils and fins in lieu of copper coils w/ aluminum fins. End plates galvanized unless otherwise specified. |

| / MAC | Make-Up Air Inlet Rain Cap |

| / EXP | Export Crate, heavy-duty, for rough handling and marine shipment |

(*) Explosion-proof heaters rated Temp Code T2A unless otherwise specified. Electric heaters for Div. 1 are field installed discharge air duct.

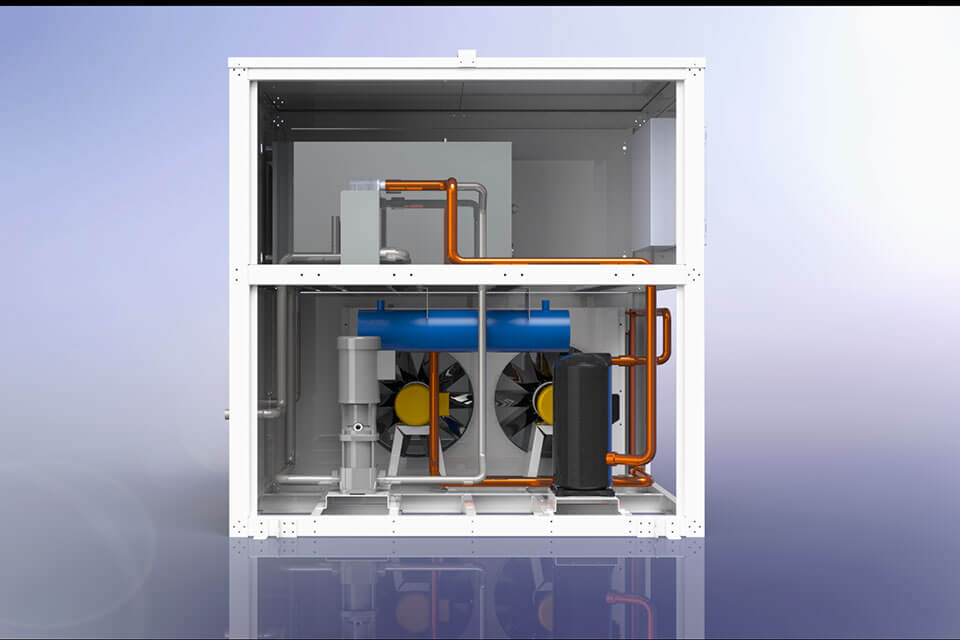

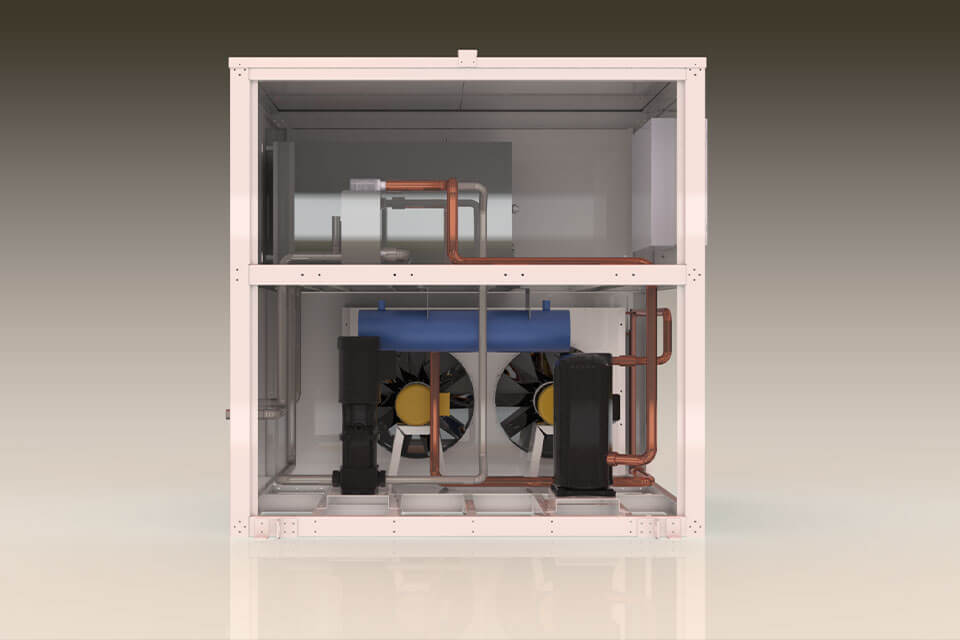

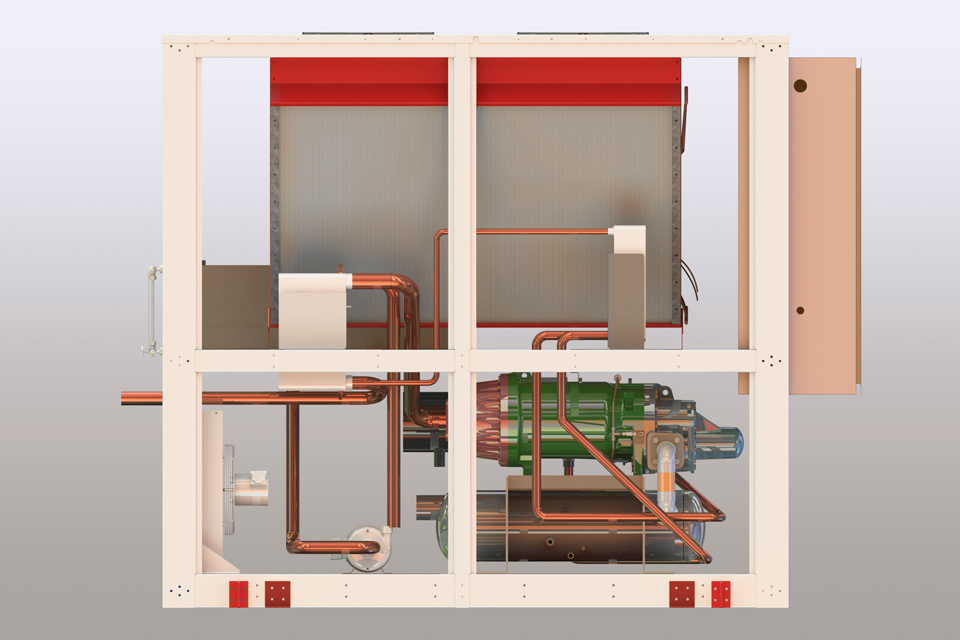

You may require a custom industrial chiller for any of the following reasons: for resistance to corrosion; for physical configuration of a machine to fit your installation; for special controls, instrumentation or electrics relating to your application: for special components (pumps, motors, compressors, tanks) providing different capacities: for unusual temperature requirements; for unique safety features; for company specified paints and finishes.

We have more than 30-years’ experience understanding diverse customers’ differing requirements, so we have a strong base from which to offer our services. Working closely with our customers, we design, build, test and deliver custom industrial chillers to remedy each and every cooling need that we consider to be within our capability.

For help in determining your custom industrial chiller requirements, call us at 225-926-6950.

Custom Design Features of Custom Industrial Chillers

Custom industrial chillers are ordered primarily for the following features:

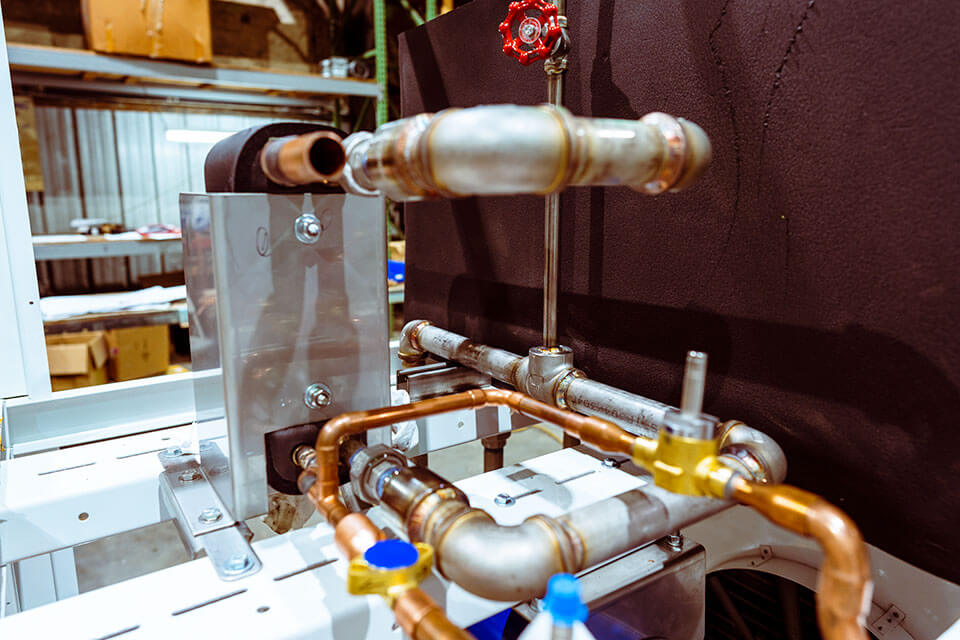

By using stainless steel frames and covers; and to the coolant by using exotic materials to prevent corrosion of the coolant circuit. Though GCI standard custom industrial chillers employ all stainless steel and copper in contact with your coolant, specialized materials are available – cu pro-nickel for use with sea water, plastic piping or stainless steel for deionized water.

Custom industrial chillers can be controlled in unique ways. Remote sensors can monitor process parameters and control the cooling to make the process operate in the optimum manner. Remote controls allow placement of custom industrial chillers in distant locations, whereas the controls can remain in a more convenient place.

Virtually any temperature range that you can envision can be accommodated.

Two complete refrigeration systems (dual compressors) can be fitted for those applications with widely varying loads or where redundancy (back-up) is important.

If your application requires a physical configuration that is different, GCI can accommodate individual needs. For instance, a customer once asked for a workstation arrangement required by a machine tool manufacturer for cooling a high-speed spindle. Other unique configurations include designs to fit inside the customer’s system.

Explosion-pyroelectric are necessary for situations where the custom industrial chiller must operate in hazardous atmospheres. Where hazardous conditions always exist (Div. 1 specification), special electricals are mandated. When the hazardous conditions do not always exist (Div. 2 specification),purged or pressurized electrical enclosures offer the required safety at reasonable cost.

Unusual electrical specifications for custom industrial chillers can include uncommon voltages, sealed systems for “wash-down” applications in food operations, etc.

Self-priming pumps or pumps of unusual metallurgy can be specified; or pumps can be fitted with special motors or impellers to provide high pressure or high flow.

Standard Options

More easily produced than a custom industrial chiller, a standard GCI chiller can incorporate any of the following options at modest cost:

- Special paints and colors

- Outdoor installation packages

- Special temperature controllers, digital or analog

- Special instrumentation

- Mounting clips or casters

- Remote switching

- Large/small tanks

- No tank

- Arranged for once-through cooling

- Additional safety switches: low flow, low temperature, high temperature, low water pressure, etc.

We’re ready to help you determine the correct capacity for your custom industrial chiller.

How to Specify a Custom Industrial Chiller

Temperature – The primary specification to be determined is the coolant temperature required. Whatever temperature the process requires. the coolant will normally have to be 5°F to 20°F cooler. Does your process need +50°F or -50°F? Capacity How many Btus per hour or minute (or watts or KgCal) are needed? If you do not know, we can help you derive that figure. Often the amount of cooling desired can be ascertained from the power consumption: For example, cooling down a kettle that was heated by a 3000-watt heater for an hour is likely to require 3000 watts of cooling to re-cool in an hour.

Some rules of thumb are:

- 1,000 walls = 3,413 Btu

- 1 horsepower = 2,545 Btu

- Cooling or heating 1 pound of water 1°F = 1 Btu

- Cooling or heating 1 gallon of water 1°F = 8.3 Btu

- Cooling or heating 1 gallon per minute of water flow by 1°F = 500 Btu/hr

- 1 refrigeration =12,000 Btu/hr

Special Materials for Custom Industrial Chillers

If the coolant must be deionized water, you will need all stainless steel and/or plastic construction. Sea water requires cu pro-nickel. Some food or medical applications will require stainless steel exteriors. Tell us your parameters. Coolant Flow and Storage – The heat transfer coolant (normally water or water and anti-freeze) may require:

- High-pressure to achieve the needed flow through tiny passages

- High flow to achieve the required turbulence

- Large tank as a thermal flywheel or shock absorber

The Physical Configuration of Custom Industrial Chillers

Does your application require a special configuration? Custom industrial chillers can be tall and thin or long and low. They can be built for indoor or outdoor location or can be split systems. We look for you to tax our abilities with your requirements. Our challenge is to design and build cost-effective custom industrial chiller to dependably meet your special needs.

Customers for GCI Custom Industrial Chillers Include:

- AT&T

- Abbott Laboratories

- Allen Bradley

- Armco

- Cincinnati Milacron

- Corning

- Dart Container

- Dow Chemical

- E.I. du Pont de Nemours

- Fischer N.A.

- FMC

- Ford

- Fresnel Optical

- General Electric

- General Motors

- W.R. Grace

- Hercules

- Hershey Foods

- Himont

- Hoechst Celanese

- ICI Americas

- Lily Cup

- Monsanto

- Motorola

- Nordion International (AECL)

- Olin Pratt & Whitney

- Procter & Gamble

- Seagate Technology

- Solo Cup

- Stanford Linear Accelerator Center

- Sweetheart Cup

- TRW

- Union Carbide

- United Technologies

- US Naval Research

- US Army R&D Center

- Weldon Machine Tool

- Whitnon Spindle Div., GMN

- Xerox